3D Recognition module

The 3D recognition module was developed to optimise the performance and simplify control of the salmon slicer TN200 V364.

It can be added to the TN200 V364 slicer, even if already installed. Depending on the age of the unit, a component upgrade may be required.

Connected to the TN200 V364 salmon slicer, the 3D vision module :

– removes the need to create or update the slicing program library ;

– increases the slices percentage obtained from the target.

Technical features

Construction : Stainless steel

Dimensions : 1928x960x2533 mm

Power supply : from the TN 200 V364

Power : 0,5 kw

Pneumatic equipment : maximum pressure: 6 bars

Specifications

Fillet temperature: -8°C/-12°C (case of farmed smoked salmon varies with the fat content)

Laser Classification: Class 2 Laser

Full tray scan: 4.2 seconds

Cutting angle: 6° – 38°

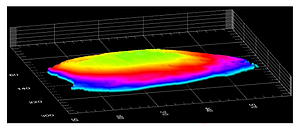

The weight and shape of each fillet are taken into account by the calculation system to create a slicing program (angles and thicknesses) appropriate to the previously entered product specifications (target weight and thickness of the slices).

Individual slicing programs for each type of raw material and finished product (creation of multiple programs, updates, etc.) are replaced by a simple library of finished products with their specifications.

The 3D recognition module is controlled via the touch screen of the salmon slicer TN 200 V364.

The 3D recognition module is generally installed within the framework of an operation on line supplements with a batching module DDV 400.

In this case it is also connected with other equipment of the line, in particular the dynamic scales.

Dans la même catégorie

1-Slicer TN200 V364

Slicer TN200 V364The TN 200 is currently in service with several of the best known smoked salmon manufacturers in France, Germany, Spain, Scotland, Belgium, Poland, Switzerland and Canada.The TN 200 is the reference slicer for smoked fish fillets: HIGH QUALITY OF...

2-Batching module DDV400

Batching Module DDV400Located post-slicing, the DDV 400 module produces batches of slices with a fixed weight and/or a fixed number of slices. Each station can produce a specific work : type of slices which will be stopped, plate sizes, batches characteristics.Many...

3-Slicer TCM300A

Slicer TCM300APROCONCEPT has specifically designed the TCM 300A slicer for companies that carry out manual packaging of slices and wish to obtain very good performance in terms of slicing quality and productivity. The TCM 300A slicer uses the same principle as the...

5-Complete solutions

Complete solutionsPROCONCEPT can offer a technical service taking into account all the steps in a process. The proposed solution will be determined based on the customer’s requirements.PROCONCEPT proposes a complete turn key solution. Regarding the main...

7-Special machines

Special machinesPROCONCEPT can study, design and manufacture special machines custom-made to suit your specific needs. Its experience in custom machines and in the food-processing business endows PROCONCEPT with the know-how to offer technical solutions that are...

6-Conveyor equipment

Conveyor equipmentPROCONCEPT manufactures various conveyors and workstations to optimise your performances: - Reduced number of stations- Increased productivity- Reduced physical strain- Reduced manual handling for better hygieneAll the equipment are designed with the...

4-Interleaver module

Interleaver moduleProconcept has designed the interleaver module to allow industrials of smoked salmon to put interleaves (which are a real bonus for consumers and frequently asked by them) without the prohibitive cost of the usual manual distribution.Interleaver...